Kufotokozera

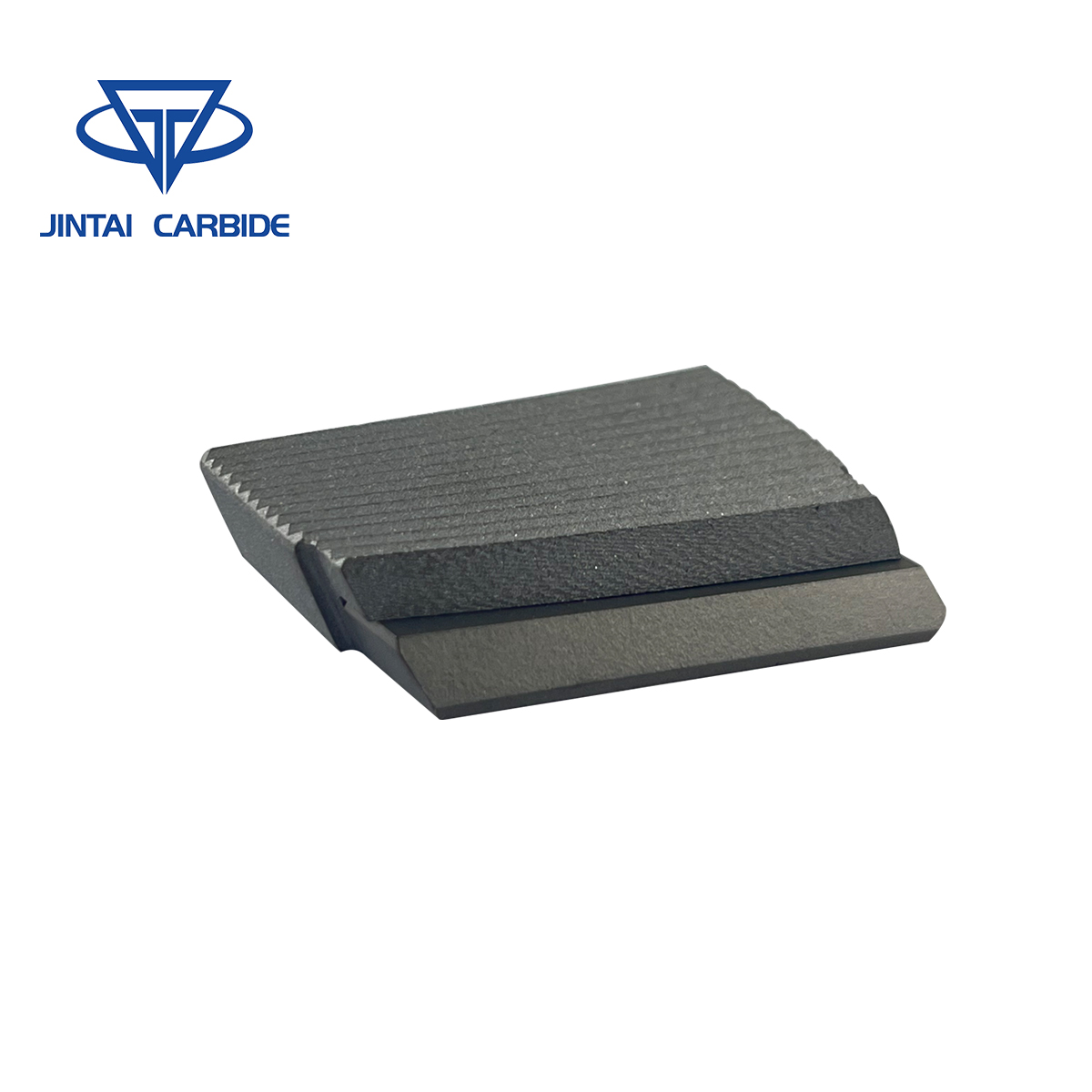

"JinKupondaponda kwa Tai kumwalira ndipo mutu wozizira umafa

Mawonekedwe:

Sankhani giredi yoyenera kutengera momwe kasitomala amagwiritsira ntchito komanso zinthu zomwe zikukonzedwa.Ndi mitundu yosiyanasiyana ya tungsten zitsulo zopondaponda, zimatha kukwaniritsa zofunikira pakugwiritsa ntchito zosiyanasiyana, mawonekedwe athunthu, miyeso yopanda kanthu, kuchepetsa kuchuluka kwa ma processing, ndikuwongolera magwiridwe antchito komanso kukwera mtengo.

Kachitidwe:

Pogwiritsa ntchito 99.95% yoyera kwambiri ya tungsten carbide ufa ndi cobalt, kuuma kwa mutu wozizira kumafika pamwamba pa HRA88, mphamvu yopindika imaposa 2400, ndi kuuma kofiira kwambiri, kukana kuvala kwambiri, modulus yotanuka kwambiri, mphamvu yopindika kwambiri, komanso kukana kolimba. .

Mapulogalamu:

Oyenera mutu ozizira ndi ozizira extrusion zigawo muyezo zopangidwa mkuwa, aluminiyamu, chitsulo, aloyi zitsulo zipangizo, monga zomangira, rivets, etc. Mitundu wamba monga lathyathyathya mutu ozizira mutu amafa, recessed mutu ozizira mutu umafa, nkhonya imodzi-modzi ndi kufa, kuchepetsa ndodo kufa, etc.

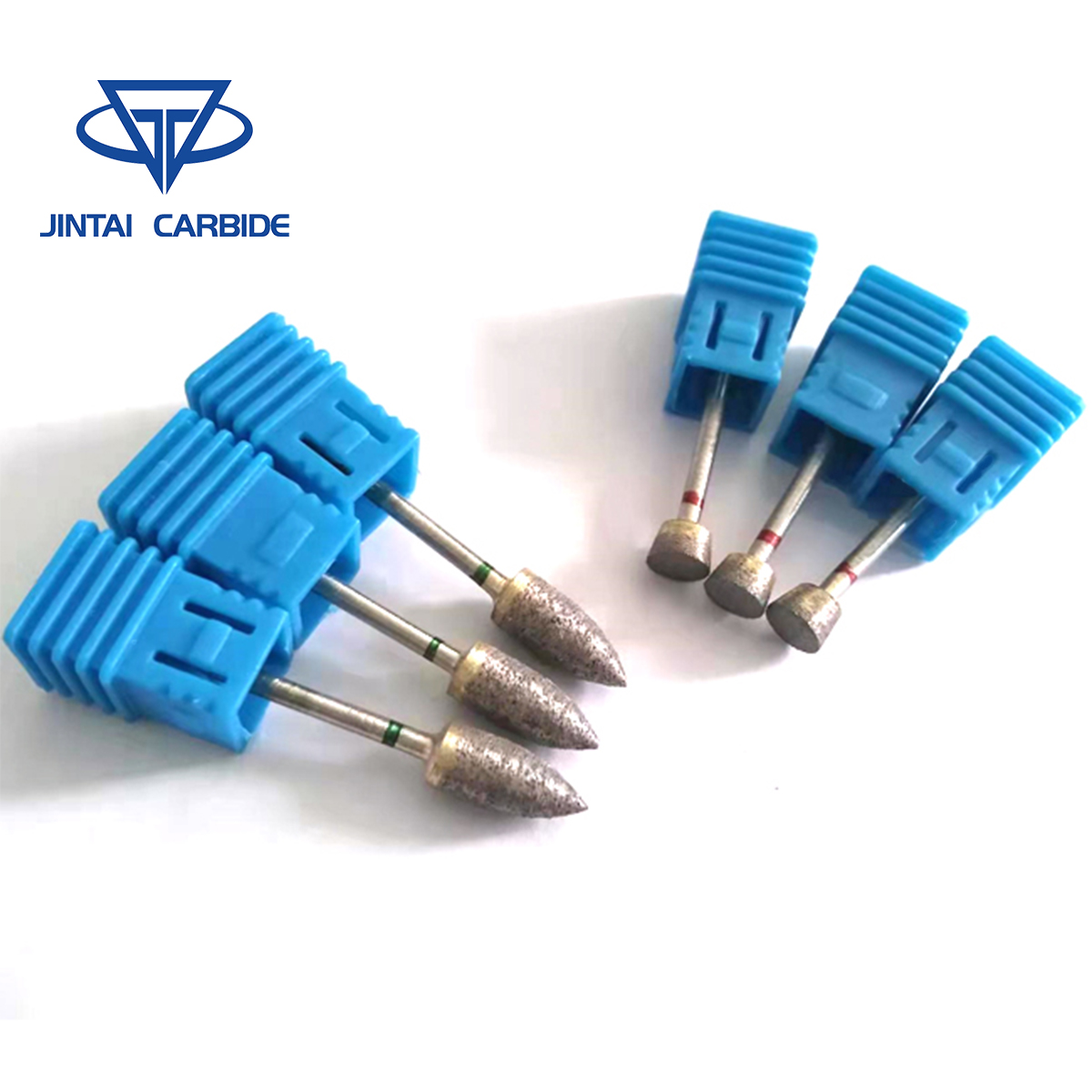

Kupondaponda Kumafa Mutu Wozizira Ufa

Mawonekedwe:

Sankhani giredi yoyenera kutengera momwe kasitomala amagwiritsira ntchito komanso zinthu zomwe zikukonzedwa.Ndi magiredi angapo amtundu wa tungsten zitsulo zopondaponda, zimatha kukwaniritsa zofunikira pakugwiritsa ntchito mosiyanasiyana, mawonekedwe athunthu, miyeso yopanda kanthu, kuchepetsa kuchuluka kwa ma processing, ndikuwongolera magwiridwe antchito ndikuchepetsa ndalama.

Kachitidwe:

Pogwiritsa ntchito 99.95% yoyera kwambiri ya tungsten carbide ufa ndi cobalt, kuuma kwa mutu wozizira kumafika pamwamba pa HRA88, mphamvu yopindika imaposa 2400, ndi kuuma kofiira kwambiri, kukana kuvala kwambiri, modulus yotanuka kwambiri, mphamvu yopindika kwambiri, komanso kukana kolimba. .

Mapulogalamu:

Oyenera mutu ozizira ndi ozizira extrusion zigawo muyezo zopangidwa mkuwa, aluminiyamu, chitsulo, aloyi zitsulo zipangizo, monga zomangira, rivets, etc. Mitundu wamba monga lathyathyathya mutu ozizira mutu amafa, recessed mutu ozizira mutu umafa, nkhonya imodzi-modzi ndi kufa, kuchepetsa ndodo kufa, etc.

Kukana kwa corrosion ndikofunikira pankhani yosunga mawonekedwe apamwamba komanso kugwira ntchito kwanthawi yayitali.Ma tungsten carbide athu amafa adapangidwa kuti azitha kukana dzimbiri.Nkhungu izi zimalimbana ndi dzimbiri ndipo zimasunga malo anu pamalo abwino, ndikuwonetsetsa kutha bwino nthawi zonse.Mutha kukhulupirira nkhungu zathu kuti zitha kuyeserera nthawi ndikupereka zotsatira zabwino kwambiri pogwiritsa ntchito nthawi iliyonse.

Kaya ndi mapangidwe apadera, kukula kwapadera kapena zofunikira zinazake, gulu lathu la akatswiri ladzipereka kuti lipereke nkhungu zomwe zimaposa zomwe mukuyembekezera.

Kukana kwa corrosion ndikofunikira pankhani yosunga mawonekedwe apamwamba komanso kugwira ntchito kwanthawi yayitali.Ma tungsten carbide athu amafa adapangidwa kuti azitha kukana dzimbiri.Nkhungu izi zimalimbana ndi dzimbiri ndipo zimasunga malo anu pamalo abwino, ndikuwonetsetsa kutha bwino nthawi zonse.Mutha kukhulupirira nkhungu zathu kuti zitha kuyeserera nthawi ndikupereka zotsatira zabwino kwambiri pogwiritsa ntchito nthawi iliyonse.

Kaya ndi mapangidwe apadera, kukula kwapadera kapena zofunikira zinazake, gulu lathu la akatswiri ladzipereka kuti lipereke nkhungu zomwe zimaposa zomwe mukuyembekezera.

Tsegulani luso lolondola la Tungsten Carbide Molds!Monga katswiri wodziwa malonda a e-commerce, mwafika pamalo abwino opangira ma Tungsten Carbide Molds apamwamba kwambiri omwe amapambana pamapangidwe osiyanasiyana, kuwonetsetsa kuti ndizolondola komanso zolimba.

Opangidwa mwaluso ndi ukadaulo wosayerekezeka, ma Tungsten Carbide Molds athu amawonetsa kuuma modabwitsa komanso kukana kuvala, zomwe zimawapangitsa kukhala chisankho chomaliza chopanga ntchito zamafakitale monga zamagalimoto, zamagetsi, ndi zina zambiri.Khulupirirani nkhungu izi kuti zipereke zotsatira zabwino komanso moyo wautali, ndikusinthira njira zanu zowumba.

Kupitilira kulimba kwawo kwapadera, ma Tungsten Carbide Molds athu amawonetsa kukana kutentha, kutsimikizira kugwira ntchito kosasintha ngakhale pakakhala kutentha kwambiri.Dziwani kuthekera kwawo kosunga mawonekedwe ake ndi kudalirika, kukupatsani mphamvu kuti muwonjezere zokolola ndikuchepetsa mtengo wopangira.

Ku JINTAI, timanyadira kwambiri popereka zinthu zomwe zimaposa miyezo yapamwamba kwambiri.Tungsten Carbide Mould iliyonse imayesedwa mwamphamvu, kuwonetsetsa kufanana komanso kuchita bwino, kukuthandizani kuti mupeze zotsatira zabwino pamapulojekiti anu akuumba.

Landirani zogwira mtima komanso zotsika mtengo ndi ma Tungsten Carbide Molds athu apamwamba kwambiri, ndikupeza mwayi wampikisano pantchito yanu.Gwirizanani nafe lero kuti muwone momwe nkhungu izi zimabweretsa pakuumba kwanu.

Sankhani JINTAI ya Tungsten Carbide Moulds odalirika, ochita bwino kwambiri, ndikuwona kuthekera kwawo kwenikweni pakukweza bizinesi yanu pampando watsopano.Ikani oda yanu tsopano ndikugwiritsa ntchito mphamvu zamayankho athu apamwamba kwambiri.

Mndandanda wa Maphunziro

| Gulu | ISO kodi | Katundu Wakuthupi (≥) | Kugwiritsa ntchito | ||

| Kuchulukana g/cm3 | Kulimba (HRA) | TRS N/mm2 | |||

| YG3X | k05 | 15.0-15.4 | ≥91.5 | ≥1180 | Oyenera makina olondola achitsulo choponyedwa ndi zitsulo zopanda chitsulo. |

| YG3 | k05 | 15.0-15.4 | ≥90.5 | ≥1180 | |

| YG6X | K10 | 14.8-15.1 | ≥91 | ≥1420 | Oyenera mwatsatanetsatane machining ndi theka-kumaliza chitsulo kuponyedwa ndi zitsulo sanali achitsulo, komanso pokonza zitsulo manganese ndi kuzimitsidwa zitsulo. |

| YG6A | K10 | 14.7-15.1 | ≥91.5 | ≥1370 | |

| YG6 | K20 | 14.7-15.1 | ≥89.5 | ≥1520 | Oyenera kumalizitsa pang'onopang'ono komanso kupangira chitsulo chonyezimira ndi ma aloyi opepuka, ndipo angagwiritsidwenso ntchito popanga chitsulo chonyezimira ndi chitsulo chochepa cha alloy. |

| YG8N | K20 | 14.5-14.9 | ≥89.5 | ≥1500 | |

| YG8 | K20 | 14.6-14.9 | ≥89 | ≥1670 | |

| YG8C | K30 | 14.5-14.9 | ≥88 | ≥1710 | Oyenera kubowola mwala mozungulira komanso pobowola miyala yozungulira. |

| YG11C | K40 | 14.0-14.4 | ≥86.5 | ≥2060 | Oyenera kuyika tinthu tating'onoting'ono tokhala ngati chisel kapena ma conical pamakina obowola miyala yolemetsa kuti athe kuthana ndi miyala yolimba. |

| YG15 | K30 | 13.9-14.2 | ≥86.5 | ≥2020 | Oyenera kuyesedwa kwamphamvu kwazitsulo zazitsulo ndi mapaipi achitsulo pansi pa kukakamiza kwakukulu. |

| YG20 | K30 | 13.4-13.8 | ≥85 | ≥2450 | Oyenera kupanga masitampu amafa. |

| YG20C | K40 | 13.4-13.8 | ≥82 | ≥2260 | Oyenera kupanga kuzizira kopondaponda ndi kukanikiza kozizira kumafa m'mafakitale monga magawo wamba, mayendedwe, zida, ndi zina. |

| YW1 | M10 | 12.7-13.5 | ≥91.5 | ≥1180 | Oyenera kukonza mwatsatanetsatane ndi theka kumaliza zitsulo zosapanga dzimbiri ndi zitsulo zonse aloyi. |

| YW2 | M20 | 12.5-13.2 | ≥90.5 | ≥1350 | Oyenera kutsirizitsa theka la chitsulo chosapanga dzimbiri ndi chitsulo chochepa cha alloy. |

| YS8 | m05 | 13.9-14.2 | ≥92.5 | ≥1620 | Oyenera kupanga makina opangidwa ndi chitsulo, nickel-based high-temperature alloys, ndi chitsulo champhamvu kwambiri. |

| YT5 | p30 | 12.5-13.2 | ≥89.5 | ≥1430 | Zoyenera kudula zitsulo ndi zitsulo zolemera kwambiri. |

| YT15 | P10 | 11.1-11.6 | ≥91 | ≥1180 | Oyenera makina mwatsatanetsatane ndi theka-kumaliza zitsulo ndi chitsulo choponyedwa. |

| YT14 | P20 | 11.2-11.8 | ≥90.5 | ≥1270 | Oyenera kukonza mwatsatanetsatane komanso kutsirizitsa zitsulo ndi chitsulo chosungunuka, ndi chakudya chochepa.YS25 idapangidwa mwapadera kuti ipange mphero pazitsulo ndi chitsulo. |

| YC45 | P40/P50 | 12.5-12.9 | ≥90 | ≥2000 | Oyenera zida zodulira zolemetsa, zomwe zimapereka zotsatira zabwino kwambiri pakutembenuza movutikira kwa ma castings ndi zitsulo zosiyanasiyana. |

| YK20 | K20 | 14.3-14.6 | ≥86 | ≥2250 | Zoyenera kuyikamo tinthu tating'onoting'ono tobowola mwala ndikubowola m'miyala yolimba komanso yolimba. |

Order Process

Njira Yopanga

Kupaka